Product Description

You can choose the 1 type that you need form these product introction.

If you have any question,please contact me.

HangZhou CHINAMFG Machinery Co.,ltd is a company specialized in research, manufacture and service of speed gearbox. Ever since establishment, we have been persisting in technical innovation, advancing the techonology to our products while maintaining our strict quality controls. It is the reason that our products branding ''Xihu (West Lake) Dis.n'' have enjoyed such successful global sales.

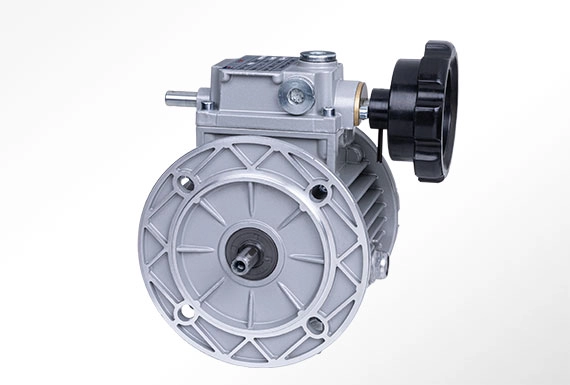

At present, our company mainly supplies 5 series products as RV worm gearbox, UDL series speed variator,PC series helical gear unit,G3 helical geared motor and SRC helical gearbox. The products are widely applied in the mechanical equipment field such as food and beverage,cement,package,chemical and dyeing, rubber and plastic, CNC machine tool,etc.

Our products have been processed ISO 9001 Quality System Certification and exported to Italy,Spain,Britain,Poland,Turkey.The USA and other European countries,earn the good reputation with our outstanding quality and service.

Customers first,customers satisfaction, excellent after sale service and incessant innovation are our tenet and motto. We will go all out to provide all the customers with high quality and service. /* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(",").forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Motor, Electric Cars, Motorcycle, Machinery, Marine, Toy, Agricultural Machinery, Car |

|---|---|

| Hardness: | Hardened Tooth Surface |

| Installation: | Vertical and Horizontal |

| Samples: |

US$ 69.9/Piece

1 Piece(Min.Order) | Order Sample |

|---|

| Customization: |

Available

|

|

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

What role do variators play in enhancing fuel efficiency in vehicles and machinery?

Variators, particularly those used in vehicles and machinery equipped with continuously variable transmissions (CVTs), play a crucial role in enhancing fuel efficiency. By optimizing the power delivery and enabling the engine to operate more efficiently, variators contribute to reducing fuel consumption and improving overall energy efficiency. Here's a detailed explanation of the role variators play in enhancing fuel efficiency:

1. Continuous Adjustment of Gear Ratio:

Variators in CVTs allow for the continuous adjustment of the gear ratio within their operating range. This means that the engine can operate at the most efficient speed for a given driving condition. By continuously optimizing the gear ratio based on the vehicle's speed and load, variators enable the engine to stay within its optimal power band, where fuel efficiency is highest. This continuous adjustment ensures that the engine operates at the most efficient RPM (revolutions per minute) for a given speed, resulting in improved fuel efficiency.

2. Elimination of Inefficient Gear Shifts:

Traditional transmissions with discrete gear ratios require frequent gear shifts during acceleration or deceleration. These gear shifts can lead to inefficient engine operation and increased fuel consumption. In contrast, variators in CVTs eliminate the need for gear shifts altogether. The smooth and continuous adjustment of the gear ratio provided by variators ensures that the engine can maintain a consistent and optimal speed, even during changes in vehicle speed. This elimination of inefficient gear shifts helps to improve fuel efficiency by maintaining the engine within its efficient operating range.

3. Precise Engine Control:

Variators enable precise control of the engine speed, allowing for finer adjustments to match the desired vehicle speed. This precise engine control ensures that the engine operates within its most efficient range. Variators continuously optimize the gear ratio based on factors such as throttle input and vehicle speed, ensuring that the engine operates at the optimal RPM for the given driving conditions. By fine-tuning the engine speed, variators help to minimize unnecessary fuel consumption and maximize fuel efficiency.

4. Adaptive Power Delivery:

Modern variators in CVTs often feature advanced control systems that adapt the power delivery to match the driver's demands and the road conditions. These control systems monitor various parameters, such as throttle input, vehicle speed, and engine load, and adjust the gear ratio accordingly. This adaptive power delivery ensures that the engine operates efficiently in real-time, optimizing fuel consumption. By adjusting the gear ratio based on the specific driving conditions, variators contribute to improved fuel efficiency by delivering the right amount of power for the desired performance.

5. Optimal Use of Engine Torque:

Variators facilitate optimal use of the engine's torque characteristics. They can be designed to provide a wide range of gear ratios, allowing the engine to operate at the most efficient torque levels for a given speed. By utilizing the available engine torque effectively, variators help to reduce the strain on the engine and improve fuel efficiency. This optimal use of engine torque ensures that the engine doesn't have to work harder than necessary, resulting in reduced fuel consumption.

6. Energy Recovery and Regeneration:

Some variators in hybrid vehicles or machinery configurations are designed to incorporate energy recovery and regeneration mechanisms. These systems capture and store energy that would otherwise be wasted during deceleration or braking. By converting the kinetic energy into electrical energy and storing it in a battery or capacitor, the energy can be reused to power the vehicle or machinery during acceleration. This energy recovery and regeneration feature helps to improve overall energy efficiency and reduce fuel consumption.

In summary, variators, especially in vehicles and machinery equipped with CVTs, play a crucial role in enhancing fuel efficiency. They achieve this by providing continuous adjustment of the gear ratio, eliminating inefficient gear shifts, enabling precise engine control, facilitating adaptive power delivery, optimizing the use of engine torque, and incorporating energy recovery and regeneration systems. By optimizing power delivery and engine operation, variators contribute to reduced fuel consumption, lower emissions, and improved overall energy efficiency in vehicles and machinery.

Can you explain the impact of variators on the overall drivability of vehicles?

Variators have a significant impact on the overall drivability of vehicles. Their design and functionality contribute to improved performance, smoother acceleration, enhanced fuel efficiency, and better control. Here's a detailed explanation of the impact of variators on the overall drivability of vehicles:

1. Smooth and Continuous Power Delivery:

Variators, especially those used in continuously variable transmissions (CVTs), provide a smooth and continuous power delivery. Unlike traditional transmissions with fixed gear ratios, variators offer an infinite number of gear ratios within their operating range. This allows the engine to operate at its most efficient speed for a given driving condition, resulting in seamless and uninterrupted power delivery. The absence of gear shifts or abrupt changes in gear ratios enhances the overall driving experience, making it smoother and more comfortable for the driver and passengers.

2. Optimal Powerband Utilization:

Variators enable the engine to stay within its optimal powerband for a wide range of driving conditions. The continuously variable nature of variators allows the engine to operate at the RPM (revolutions per minute) range where it produces the highest torque and power. By keeping the engine within its optimal powerband, variators enhance the vehicle's responsiveness and acceleration. This results in improved drivability, especially during overtaking maneuvers or when quick acceleration is required.

3. Improved Fuel Efficiency:

Variators, particularly CVTs, contribute to improved fuel efficiency. By continuously varying the gear ratio to match the driving conditions, variators allow the engine to operate at lower RPMs during cruising or light load conditions. This keeps the engine operating at its most efficient point, reducing unnecessary fuel consumption. Additionally, variators eliminate the energy losses associated with gear shifts in traditional transmissions, further improving fuel efficiency. The improved fuel efficiency provided by variators not only lowers fuel costs but also reduces the environmental impact by lowering emissions.

4. Enhanced Control and Responsiveness:

Variators offer precise control over the powertrain, resulting in enhanced vehicle control and responsiveness. The continuously variable gear ratios allow for fine adjustments in power delivery, enabling smooth and precise acceleration or deceleration. This gives drivers more control over their vehicle's speed and performance, enhancing the overall driving experience. Variators also respond quickly to changes in throttle input, allowing for seamless transitions between different driving conditions and improving drivability in various road and traffic situations.

5. Adaptability to Driving Conditions:

Variators are adaptable to a wide range of driving conditions. They can adjust the gear ratio in real-time based on factors such as vehicle speed, throttle input, and road conditions. This adaptability allows variators to optimize power delivery for different scenarios, whether it's smooth cruising on highways, navigating city traffic, or tackling steep inclines. By automatically adjusting the gear ratio to match the driving conditions, variators enhance drivability and ensure optimal performance across various situations.

6. Reduction in Noise and Vibrations:

Variators contribute to a quieter and more refined driving experience by reducing noise and vibrations. The continuously variable nature of variators eliminates the need for gear shifts, which are often accompanied by noticeable shifts in engine noise and vibrations in traditional transmissions. With variators, the engine can operate at lower RPMs during normal driving, resulting in reduced engine noise. Additionally, the absence of gear shifts minimizes the vibrations transmitted to the vehicle, leading to a smoother and more comfortable ride.

7. Integration with Advanced Driver Assistance Systems (ADAS):

Variators can seamlessly integrate with advanced driver assistance systems (ADAS) to enhance overall drivability and safety. By providing precise control over power delivery, variators can work in conjunction with ADAS technologies such as adaptive cruise control, lane-keeping assist, and automatic emergency braking. The integration of variators with ADAS enables smoother acceleration and deceleration, improved vehicle stability, and enhanced responsiveness to potential hazards, ultimately improving the overall drivability and safety of vehicles.

In conclusion, variators have a significant impact on the overall drivability of vehicles. They provide smooth and continuous power delivery, optimize powerband utilization, improve fuel efficiency, enhance control and responsiveness, adapt to driving conditions, reduce noise and vibrations, and integrate with advanced driver assistance systems. By incorporating variators into vehicles, manufacturers can enhance the driving experience, improve performance, and achieve higher levels of efficiency and comfort for drivers and passengers.

Can you provide examples of products or machinery that use variators for speed control?

Yes, variators are used in a wide range of products and machinery for speed control purposes. The ability to adjust the gear ratio continuously makes variators ideal for applications where precise speed control is required. Here are some examples of products and machinery that utilize variators for speed control:

1. Automobiles:

In the automotive industry, variators are commonly used in continuously variable transmissions (CVTs) for speed control in passenger cars, SUVs, and other vehicles. CVTs with variators allow for seamless and continuous adjustment of the gear ratio, enabling precise speed control and efficient power delivery. Variators in automobiles contribute to improved fuel efficiency, smoother acceleration, and enhanced driving comfort.

2. Motorcycles and Scooters:

Variators are also utilized in the transmissions of motorcycles and scooters for speed control. CVTs with variators provide riders with the ability to adjust the speed output smoothly and precisely. By continuously varying the gear ratio, variators offer a responsive and customizable riding experience, allowing riders to adapt to different road conditions and riding preferences.

3. Industrial Machinery:

In industrial settings, variators are used in various types of machinery that require speed control. For example, variators can be found in conveyor systems, where they allow for precise adjustment of the conveyor belt speed to match the specific production requirements. Variators are also used in pumps, fans, mixers, and other equipment that need variable speed control to optimize performance and energy consumption.

4. Agricultural Equipment:

Agricultural machinery, such as tractors, combines, and harvesters, often utilize variators for speed control. Variators in these machines allow farmers and operators to adjust the speed according to the specific tasks at hand, such as plowing, seeding, or harvesting. This flexibility enables efficient operation in various agricultural operations and field conditions.

5. Construction and Earthmoving Equipment:

Variators are used in construction and earthmoving equipment to regulate the speed of machines like excavators, loaders, and bulldozers. By controlling the gear ratio, variators enable operators to adjust the speed of these machines, allowing for precise and efficient performance in tasks such as digging, lifting, and pushing materials.

6. Marine Applications:

Marine vessels, including boats, yachts, and ships, utilize variators for speed control. In marine applications, variators are employed to adjust the propeller speed and optimize power delivery based on the desired speed and operating conditions. Variators in marine applications offer benefits such as improved fuel efficiency, enhanced maneuverability, and smooth acceleration.

7. HVAC Systems:

Variators are used in heating, ventilation, and air conditioning (HVAC) systems for speed control of fans and blowers. By adjusting the gear ratio, variators allow for precise control of the airflow, ensuring that the fans operate at the desired speed for efficient heating, cooling, and ventilation in residential, commercial, and industrial settings.

8. Exercise Equipment:

In the fitness industry, variators are employed in exercise equipment such as treadmills, elliptical trainers, and stationary bikes. Variators enable users to adjust the speed and resistance levels of the equipment, providing a customizable workout experience to meet individual fitness goals and preferences.

In summary, variators for speed control are utilized in a wide range of products and machinery, including automobiles, motorcycles, industrial machinery, agricultural equipment, construction and earthmoving machinery, marine applications, HVAC systems, and exercise equipment. The ability to continuously adjust the gear ratio allows for precise speed control, optimizing performance and efficiency in various applications.

editor by CX 2024-03-09