Product Description

| Medium Voltage VFD | MV-1300-65 | 690V/1300V/2600V | 65-105A | 6/12 pulse optional | sinusoidal filtering | low cost, energy saving, small footprint | Control algorithm:The optimized three-level SVPWM control algorithm is adopted, and the output voltage waveform is quasi-sine wave, which is very suitable for long cable transmission application of electric submersible pump. |

| MV-1300-105 | 690V/1300V/2600V | 65-105A | 6/12 | ,, | :5,,, | ||

| Medium Voltage VFD | MV-1300-65 | 690V/1300V/2600V | 65-105A | 6/12 pulse optional | sinusoidal filtering | low cost, energy saving, small footprint | Start mode:Five optional starting modes are provided to solve the starting difficulties of the electric submersible pump when it meets sand jam, heavy oil, scale formation and so on. |

| MV-2600-65 | 690V/1300V/2600V | 65-105A | 6/12 | ,, | ,,, | ||

| Medium Voltage VFD | MV-1300-65 | 690V/1300V/2600V | 65-105A | 6/12 pulse optional | sinusoidal filtering | low cost, energy saving, small footprint | Start mode:Five optional starting modes are provided to solve the starting difficulties of the electric submersible pump when it meets sand jam, heavy oil, scale formation and so on. |

| MV-2600-105 | 690V/1300V/2600V | 65-105A | 6/12 | ,, | :RS485,MODBUS-RTU,, | ||

| Medium Voltage VFD | MV-1300-65 | 690V/1300V/2600V | 65-105A | 6/12 pulse optional | sinusoidal filtering | low cost, energy saving, small footprint | Remote control:It provides RS485 communication interface and supports standard MODBUS-RTU protocol. The VFD can be connected to the remote monitoring system in the background through wired or wireless mode to monitor and control the operation of the electric submersible pump remotely in real time |

| 690V/1300V/2600V | 65-105A | 6/12 | ,, | :, | |||

| Medium Voltage VFD | MV-1300-65 | 690V/1300V/2600V | 65-105A | 6/12 pulse optional | sinusoidal filtering | low cost, energy saving, small footprint | Frequency setting:Support a variety of frequency setting mode, so that the frequency conversion system can flexibly adapt to different applications of electric submersible pump. |

| 690V/1300V/2600V | 65-105A | 6/12 | ,, | :10,,,USB,U, | |||

| Medium Voltage VFD | MV-1300-65 | 690V/1300V/2600V | 65-105A | 6/12 pulse optional | sinusoidal filtering | low cost, energy saving, small footprint | HMI:The 10-inch industrial touch screen supports real-time switching of Chinese and English display, integrates the display and storage function of electric pump downhole sensor data, provides USB download interface, customer can use a USB disk to download and store various historical operation data, provides customized interface development |

Medium Voltage Drive is high-high voltage device, which is controlled by DSP, with the SVPWM and cell in series multi-level technology to guarantee the inverter to suit industrial fields. The harmonic content is much smaller than the standard of IEE519-1992. It has high power factor and good output wave quality without input filters, power factor compensation device and output filter. Motor heating caused by harmonics and Torque ripple, noise, dv/dt, and common mode voltage problems are also avoided. It fits for asynchronous and synchronous motors. The product was awarded as national key new products in 2003, high voltage hoister inverter was awarded as National CHINAMFG Project in 2005 and funded by Ministry of Science and Technology Innovation Fund for SMEs project.

ZheJiang Tech&Ser Petroleum Equipment Co., Ltd is a professional company integrated with scientific research, production and service of Oil field equipment. And Specialized in R&D of compressors, VFD, rotor, oil casing, screen pipes and pipelines, screw pumps, electric submersible pumps and control cabinets, petrochemicals and auxiliaries, petroleum tool accessories and labor protection supplies and Related maintenance services, etc

Now Tech&Ser company has more than 500 employees, which is headquartered in HangZhou city -the central city of the Huang river Delta. There are 2 Branches Establishment belong to Tech&Ser Company, which is in HangZhou and HangZhou City. With 5 production bases, Compressors equipment parts production base in HangZhou, ZheJiang &HangZhou's Bump production base, VFD production center and oilfield chemicals R&D center.

Tech&Ser is oriented to create value for domestic and foreign customers and partners, and is committed to providing intelligent products and high-quality services for the global oil and gas industry. The company focuses on the international business development of the oil and gas energy industry. Providing customers with integrated solutions in the field of oil and gas energy, such as R&D and manufacturing of oil and gas energy equipment, integrated services of oil and gas energy engineering and oilfield, and industry + Internet platform services.

More efficient, scientific and technological innovation is the core competitiveness of enterprise development.

Packaging & Shipping

FAQ

1. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

2.why should you buy from us not from other suppliers?

Responsibility, high quality, on time delivery

3. what services can we provide?

Accepted Delivery Terms: FOB,CIF,EXW,FCA,DDP,DDU,Express Delivery,DAF;

Accepted Payment Currency:USD,EUR,AUD,CNY;

Accepted Payment Type: T/T,PayPal,Western Union;

Language Spoken:English,Chinese

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(",").forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | High-performance Transducer, Three Phase Transducer, High Frequency Converter Transducer, High Performance Converter/Inveter |

|---|---|

| Output Type: | Single |

| Principle of Work: | V/F Control Transducer |

| Switch Mode: | PWM Control |

| Main Circuit Type: | Voltage |

| Voltage of Power Supply: | High Voltage Variable-Frequency Drive |

| Customization: |

Available

|

|

|---|

What role do variators play in enhancing fuel efficiency in vehicles and machinery?

Variators, particularly those used in vehicles and machinery equipped with continuously variable transmissions (CVTs), play a crucial role in enhancing fuel efficiency. By optimizing the power delivery and enabling the engine to operate more efficiently, variators contribute to reducing fuel consumption and improving overall energy efficiency. Here's a detailed explanation of the role variators play in enhancing fuel efficiency:

1. Continuous Adjustment of Gear Ratio:

Variators in CVTs allow for the continuous adjustment of the gear ratio within their operating range. This means that the engine can operate at the most efficient speed for a given driving condition. By continuously optimizing the gear ratio based on the vehicle's speed and load, variators enable the engine to stay within its optimal power band, where fuel efficiency is highest. This continuous adjustment ensures that the engine operates at the most efficient RPM (revolutions per minute) for a given speed, resulting in improved fuel efficiency.

2. Elimination of Inefficient Gear Shifts:

Traditional transmissions with discrete gear ratios require frequent gear shifts during acceleration or deceleration. These gear shifts can lead to inefficient engine operation and increased fuel consumption. In contrast, variators in CVTs eliminate the need for gear shifts altogether. The smooth and continuous adjustment of the gear ratio provided by variators ensures that the engine can maintain a consistent and optimal speed, even during changes in vehicle speed. This elimination of inefficient gear shifts helps to improve fuel efficiency by maintaining the engine within its efficient operating range.

3. Precise Engine Control:

Variators enable precise control of the engine speed, allowing for finer adjustments to match the desired vehicle speed. This precise engine control ensures that the engine operates within its most efficient range. Variators continuously optimize the gear ratio based on factors such as throttle input and vehicle speed, ensuring that the engine operates at the optimal RPM for the given driving conditions. By fine-tuning the engine speed, variators help to minimize unnecessary fuel consumption and maximize fuel efficiency.

4. Adaptive Power Delivery:

Modern variators in CVTs often feature advanced control systems that adapt the power delivery to match the driver's demands and the road conditions. These control systems monitor various parameters, such as throttle input, vehicle speed, and engine load, and adjust the gear ratio accordingly. This adaptive power delivery ensures that the engine operates efficiently in real-time, optimizing fuel consumption. By adjusting the gear ratio based on the specific driving conditions, variators contribute to improved fuel efficiency by delivering the right amount of power for the desired performance.

5. Optimal Use of Engine Torque:

Variators facilitate optimal use of the engine's torque characteristics. They can be designed to provide a wide range of gear ratios, allowing the engine to operate at the most efficient torque levels for a given speed. By utilizing the available engine torque effectively, variators help to reduce the strain on the engine and improve fuel efficiency. This optimal use of engine torque ensures that the engine doesn't have to work harder than necessary, resulting in reduced fuel consumption.

6. Energy Recovery and Regeneration:

Some variators in hybrid vehicles or machinery configurations are designed to incorporate energy recovery and regeneration mechanisms. These systems capture and store energy that would otherwise be wasted during deceleration or braking. By converting the kinetic energy into electrical energy and storing it in a battery or capacitor, the energy can be reused to power the vehicle or machinery during acceleration. This energy recovery and regeneration feature helps to improve overall energy efficiency and reduce fuel consumption.

In summary, variators, especially in vehicles and machinery equipped with CVTs, play a crucial role in enhancing fuel efficiency. They achieve this by providing continuous adjustment of the gear ratio, eliminating inefficient gear shifts, enabling precise engine control, facilitating adaptive power delivery, optimizing the use of engine torque, and incorporating energy recovery and regeneration systems. By optimizing power delivery and engine operation, variators contribute to reduced fuel consumption, lower emissions, and improved overall energy efficiency in vehicles and machinery.

What is the impact of variators on the lifespan of mechanical components in a system?

The impact of variators on the lifespan of mechanical components in a system is a crucial consideration. Variators, such as continuously variable transmissions (CVTs), can have both positive and negative effects on the longevity of mechanical components. Here's a detailed explanation of the impact of variators on the lifespan of mechanical components:

1. Reduced Wear and Tear:

Variators can contribute to reduced wear and tear on mechanical components compared to traditional transmissions with fixed gear steps. The continuously variable nature of variators allows for smoother and seamless gear ratio changes, eliminating the shock and stress associated with gear shifts in conventional transmissions. This smoother operation can reduce the strain on various components like gears, synchronizers, and clutch packs, potentially extending their lifespan.

2. Improved Power Delivery:

Variators optimize power delivery by continuously adjusting the gear ratios to keep the engine in its most efficient operating range. By operating the engine within its optimal powerband, variators can reduce the load and stress on mechanical components. When the engine operates more efficiently, it can lead to reduced wear on components like pistons, connecting rods, and crankshafts, potentially increasing their lifespan.

3. Enhanced Cooling and Lubrication:

Variators often incorporate advanced cooling and lubrication systems to maintain optimal operating conditions. These systems help manage heat generated during operation and ensure proper lubrication of critical components. Effective cooling and lubrication can prevent excessive heat buildup, reduce friction, and minimize wear on bearings, shafts, and other moving parts. By providing better cooling and lubrication, variators can help extend the lifespan of these mechanical components.

4. Increased Complexity and Component Interdependence:

Variators, especially electronic or computer-controlled ones, can introduce increased complexity and component interdependence within the system. The integration of electronic control systems, sensors, and actuators adds additional components that can potentially fail or require maintenance. The interdependence of these components means that a failure in one part can affect the overall performance and lifespan of the variator and other mechanical components. Proper maintenance, regular inspections, and timely repairs are crucial to mitigate potential issues and ensure the longevity of the system.

5. Maintenance and Service Requirements:

Variators may have specific maintenance and service requirements to ensure their optimal performance and longevity. Regular fluid changes, inspections, and adjustments may be necessary to keep the variator and associated mechanical components in good working condition. Adhering to the manufacturer's recommended maintenance schedule is important to prevent premature wear and failure of components. Neglecting maintenance can lead to accelerated wear, reduced lifespan, and potential costly repairs.

6. Quality of Design and Manufacturing:

The overall lifespan of mechanical components in a variator system can be influenced by the quality of design and manufacturing. Variators and their associated components should be designed and manufactured to meet specific performance and durability standards. High-quality materials, precise engineering, and stringent quality control can contribute to the longevity of mechanical components. Variators from reputable manufacturers with a track record of reliability and performance are more likely to have a positive impact on the lifespan of mechanical components.

7. Driving Habits and Operating Conditions:

The impact of variators on the lifespan of mechanical components can also be influenced by driving habits and operating conditions. Aggressive driving, excessive loading, and operating the vehicle in extreme conditions can put additional stress on the variator and associated components. Continuous high RPM operation, abrupt throttle inputs, or towing heavy loads can accelerate wear and potentially shorten the lifespan of mechanical components. Operating the vehicle within recommended limits and practicing responsible driving habits can help preserve the longevity of the system.

In conclusion, variators can have both positive and negative impacts on the lifespan of mechanical components in a system. The continuously variable nature of variators can reduce wear and tear, improve power delivery, and enhance cooling and lubrication. However, increased complexity, maintenance requirements, and the quality of design and manufacturing are factors to consider. Additionally, driving habits and operating conditions play a significant role in determining the lifespan of mechanical components. Regular maintenance, proper care, and responsible driving practices are essential to ensure the longevity of the variator system and its associated mechanical components.

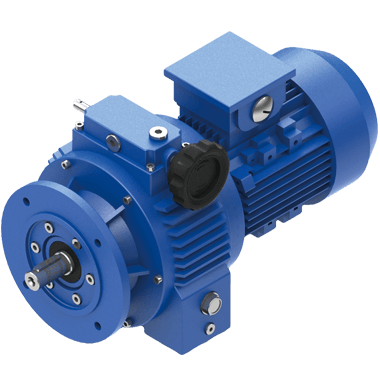

What is a variator, and how does it function in mechanical systems?

A variator is a mechanical device used in certain systems to provide variable speed or torque output. It is commonly found in applications such as belt-driven continuously variable transmissions (CVTs) and hydraulic systems. A variator allows for seamless and continuous adjustment of output speed or torque within a specific range, without the need for discrete gears or speed ratios. Here's a detailed explanation of what a variator is and how it functions in mechanical systems:

A variator typically consists of two primary components: a driving element and a driven element. The driving element is connected to the power source, while the driven element is connected to the load or output. The two elements are linked together through a set of movable parts, such as adjustable sheaves, cones, or pistons.

The function of a variator is to vary the effective diameter or contact ratio between the driving and driven elements. By changing the effective diameter, the output speed or torque can be adjusted continuously. The specific mechanism employed by a variator depends on its design and application, but the basic principle remains the same.

In a belt-driven CVT variator, for example, the driving element consists of two variable-diameter pulleys connected by a belt. The pulleys have movable sheaves that can adjust their effective diameter. By changing the position of the sheaves, the belt rides at different points on the pulleys, effectively changing the gear ratio and allowing for continuous speed variation. When the driving pulley's effective diameter increases, the belt rides higher on the pulley, resulting in a larger output speed. Conversely, when the driving pulley's effective diameter decreases, the belt rides lower, resulting in a smaller output speed.

In hydraulic systems, a variator can be achieved through the use of adjustable flow control valves or variable-displacement pumps. By adjusting the valve position or pump displacement, the flow rate and speed of the hydraulic fluid can be varied, enabling precise control of the output speed and torque.

Overall, the variator's function in mechanical systems is to provide a continuously variable output by adjusting the effective diameter, contact ratio, or flow rate. This enables smooth and seamless speed or torque variation without the need for discrete gears or speed ratios. Variators offer advantages such as improved efficiency, flexibility, and precise control in various applications, including automotive transmissions, industrial machinery, and hydraulic systems.

editor by CX 2024-03-14