Product Description

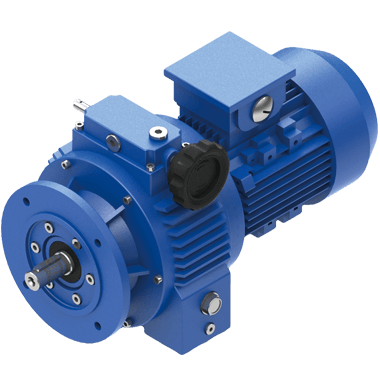

JWB Series Speed Variator

1. Features:

JWB-X type

- Sizes: ≥04

- Power up to 1.5 kW or more

- Cases in RAL 5571 blue cast iron

- Shafts: case hardened and tempered steel.

- Internal components: heat-treated steel

- Output speed with 4 pole(1400r/min) motors: 2-10r/min;4.7-23.5r/min;15-75r/min;20-100r/min, 28-140r/min, 30-150r/min;40-200r/min;60-300r/min;80-400r/min;100-500r/min;190-950r/min.

- Output Torque value max 1002Nm

- Silent, vibration-free running

- Bidirectional rotation

- Control handwheel positionable on either side

- Slipping speed to max load at 5%

- Regulation sensibility: 0,5 rpm

- Painted with blue epoxy-polyester powder

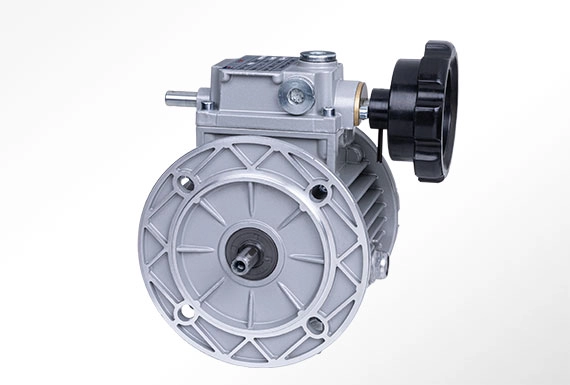

JWB-X B type

- Sizes:01,02,03 and 04

- Power up to 1.5 kW or less

- Cases in die-cast aluminium alloy

- Shafts: case hardened and tempered steel.

- Internal components: heat-treated steel

- Output speed with 4 pole(1400r/min) motors: 2r/min-20r/min;4.7r/min-23.5r/min;6.5-32.5r/min, 8-40r/min, 9-45r/min, 13-65r/min, 15r/min-75r/min;18-90r/min, 25-125r/min, 28r/min-140r/min;40r/min-200r/min;60r/min-300r/min;80r/min-400r/min;100r/min-500r/min;190r/min-950r/min.

- Output Torque value max 795 Nm

- Silent, vibration-free running

- Bidirectional rotation

- Control hand wheel positionable on either side

- Slipping speed to max load at 5%

- Regulation sensibility: 0,5 rpm

- Painted with blue epoxy-polyester powder

2. Technical parameters

| Type | Output Torque | Output Shaft Dia. | Output Speed Range | 2rpm-950rpm | |

| SWB01 | 2.6-1.6N.m | φ11 | Applicable Motor Power | 0.18kW-7.5kW | |

| SWB02 | 258-1.8N.m | φ14,φ24,φ28,φ32 | |||

| SWB03 | 426-4N.m | φ24,φ28,φ38 | Input Options | With Inline AC Motor | |

| SWB04 | 795-8N.m | φ28,φ38,φ42 | With IEC Motor | ||

| SWB05 | 535-16N.m | φ38,φ48,φ55 | With Input Shaft | ||

| SWB06 | 1002-40N.m | φ42,φ55,φ70 | With Input Flange | ||

About Us

ZheJiang CHINAMFG Drive Co.,Ltd,the predecessor was a state-owned military mould enterprise, was established in 1965. CHINAMFG specializes in the complete power transmission solution for high-end equipment manufacturing industries based on the aim of "Platform Product, Application Design and Professional Service".

CHINAMFG have a strong technical force with over 350 employees at present, including over 30 engineering technicians, 30 quality inspectors, covering an area of 80000 square CHINAMFG and kinds of advanced processing machines and testing equipments. We have a good foundation for the industry application development and service of high-end speed reducers & variators owning to the provincial engineering technology research center,the lab of gear speed reducers, and the base of modern R&D.

Our Team

Quality Control

Quality:Insist on Improvement,Strive for Excellence With the development of equipment manufacturing indurstry,customer never satirsfy with the current quality of our products,on the contrary,wcreate the value of quality.

Quality policy:to enhance the overall level in the field of power transmission

Quality View:Continuous Improvement , pursuit of excellence

Quality Philosophy:Quality creates value

3. Incoming Quality Control

To establish the AQL acceptable level of incoming material control, to provide the material for the whole inspection, sampling, immunity. On the acceptance of qualified products to warehousing, substandard goods to take return, check, rework, rework inspection; responsible for tracking bad, to monitor the supplier to take corrective

measures to prevent recurrence.

4. Process Quality Control

The manufacturing site of the first examination, inspection and final inspection, sampling according to the requirements of some projects, judging the quality change trend;

found abnormal phenomenon of manufacturing, and supervise the production department to improve, eliminate the abnormal phenomenon or state.

5. FQC(Final QC)

After the manufacturing department will complete the product, stand in the customer's position on the finished product quality verification, in order to ensure the quality of

customer expectations and needs.

6. OQC(Outgoing QC)

After the product sample inspection to determine the qualified, allowing storage, but when the finished product from the warehouse before the formal delivery of the goods, there is a check, this is called the shipment inspection.Check content:In the warehouse storage and transfer status to confirm, while confirming the delivery of the

product is a product inspection to determine the qualified products.

7. Certification.

Packing

Delivery

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(",").forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Motor, Agricultural Machinery, Ceramic |

|---|---|

| Hardness: | Hardened Tooth Surface |

| Installation: | Vertical or Horizotal Type |

| Layout: | Coaxial |

| Gear Shape: | Planetary Conedisk Friction Type |

| Step: | Stepless |

| Customization: |

Available

|

|

|---|

What factors should be considered when selecting a variator for different industrial applications?

When selecting a variator for different industrial applications, several factors need to be considered to ensure optimal performance and compatibility. Here are the key factors that should be taken into account:

1. Load Requirements:

The first factor to consider is the load requirements of the specific industrial application. Determine the torque and power demands of the machinery or equipment that the variator will be driving. It is essential to select a variator that can handle the anticipated load conditions without exceeding its maximum torque or power capabilities. Consider factors such as starting torque, peak torque, and continuous torque requirements to ensure the variator can handle the load effectively.

2. Speed Range:

Consider the required speed range for the application. Determine the minimum and maximum speeds that the variator needs to achieve. Variators are designed to operate within specific speed ranges, so it is crucial to select a model that can accommodate the required speed range while maintaining optimal performance. Additionally, consider the desired speed resolution or increments required for precise speed control.

3. Environmental Conditions:

Take into account the environmental conditions in which the variator will operate. Factors such as temperature, humidity, dust, and vibration levels can impact the performance and longevity of the variator. Choose a variator that is designed to withstand the specific environmental conditions of the industrial application. For example, some variators are specifically designed for harsh or hazardous environments and have enhanced protection against dust, moisture, or extreme temperatures.

4. Control System Integration:

Determine how the variator will integrate with the control system of the industrial application. Consider compatibility with existing control interfaces or protocols, such as analog, digital, or fieldbus systems. Ensure that the variator can be easily integrated into the control architecture of the machinery or equipment, allowing for seamless communication and control. Compatibility with programmable logic controllers (PLCs) or other control devices should also be evaluated.

5. Operational Efficiency:

Evaluate the operational efficiency of the variator. Look for features that contribute to energy efficiency, such as low power losses or regenerative capabilities. A variator that operates efficiently can help reduce energy consumption, lower operating costs, and minimize the environmental impact. Consider features like automatic energy optimization, energy monitoring, or sleep modes that can enhance the overall efficiency of the variator.

6. Maintenance and Serviceability:

Consider the ease of maintenance and serviceability of the variator. Look for features that simplify maintenance tasks, such as accessible components, user-friendly interfaces, and diagnostic capabilities. Additionally, consider the availability of spare parts and the reputation of the manufacturer or supplier in terms of customer support and after-sales service.

7. Cost and Budget:

Finally, evaluate the cost of the variator and its alignment with the budget for the industrial application. Consider the initial purchase cost as well as the long-term operational costs, including energy consumption, maintenance, and potential downtime. It is important to strike a balance between the desired features, performance, and cost-effectiveness to ensure the best value for the specific application.

By considering these factors - load requirements, speed range, environmental conditions, control system integration, operational efficiency, maintenance and serviceability, and cost - when selecting a variator for different industrial applications, you can make an informed decision that meets the specific needs of the machinery or equipment, ensuring reliable and efficient operation.

What are the signs that indicate a need for variator repairs, and how can they be diagnosed?

Recognizing the signs that indicate a need for variator repairs is crucial for maintaining the performance and reliability of the system. Here are some common signs to watch out for and the diagnostic methods used to identify variator issues:

1. Abnormal Noise:

If you notice unusual noises coming from the variator, such as grinding, whining, or rattling sounds, it could indicate a problem. These noises may be a result of worn-out bearings, misaligned components, or damaged pulleys. To diagnose the issue, a thorough inspection of the variator, including the pulleys, belts, and bearings, can help identify the source of the noise.

2. Slipping or Inconsistent Power Transfer:

If you experience a loss of power or notice the engine revving without a corresponding increase in speed, it could indicate slipping belts or worn-out pulleys in the variator system. Inconsistent power transfer can also manifest as jerky acceleration or a delay in power delivery. Diagnosing this issue involves checking the tension and condition of the belts, as well as inspecting the pulleys for signs of wear or damage.

3. Overheating:

If the variator system becomes excessively hot during operation, it may indicate a problem. Overheating can be caused by factors such as insufficient lubrication, misalignment, or excessive friction within the variator components. Diagnosing this issue involves monitoring the temperature of the variator during operation and inspecting the lubrication levels, cooling systems, and components for any abnormalities.

4. Vibration or Shaking:

Excessive vibration or shaking during variator operation can be a sign of misaligned components, worn-out bearings, or damaged pulleys. These issues can lead to an imbalanced operation, resulting in vibrations felt throughout the machinery. To diagnose this issue, a visual inspection of the variator components and a check for any signs of wear or damage can help identify the source of the vibration.

5. Leaking Fluid:

If you notice fluid leaks around the variator system, it could indicate a problem with seals or gaskets. Leaking fluid can lead to inadequate lubrication or loss of hydraulic pressure, affecting the performance and reliability of the variator. Diagnosing this issue involves identifying the source of the leak and examining the seals, gaskets, and fluid levels for any signs of damage or wear.

6. Erratic Gear Shifting:

If the variator system exhibits erratic or inconsistent gear shifting, such as sudden jumps in gear ratio or difficulty in engaging certain gears, it may indicate a problem with the variator components or the control system. Diagnosing this issue involves inspecting the variator components, including the pulleys, belts, and control mechanisms, and checking for any misalignments, wear, or malfunctions.

7. Diagnostic Tools and Professional Inspection:

In addition to the visual inspections mentioned above, professional diagnosis of variator issues often involves the use of specialized diagnostic tools and equipment. These tools can include belt tension gauges, laser alignment devices, vibration analyzers, temperature sensors, and diagnostic software. Professional technicians with expertise in variator systems can perform comprehensive inspections and use these tools to diagnose specific problems accurately.

It's important to note that variator repairs should be carried out by trained professionals with experience in variator systems. If you notice any signs indicating potential variator issues, it is advisable to have the system inspected and repaired by a qualified technician to ensure proper diagnosis and appropriate repairs are performed.

Can you explain the role of a variator in continuously variable transmissions (CVTs)?

In continuously variable transmissions (CVTs), a variator plays a crucial role in providing seamless and continuous variation of the gear ratios. It is the key component that enables CVTs to offer a wide range of gear ratios without discrete gears. Here's a detailed explanation of the role of a variator in CVTs:

A CVT is a type of transmission that can vary the gear ratio continuously within a specific range, rather than having a fixed set of gears like traditional automatic or manual transmissions. The variator in a CVT is responsible for adjusting the gear ratio based on the driving conditions and driver inputs.

The variator in a CVT typically consists of two variable-diameter pulleys connected by a belt or chain. Each pulley has a pair of adjustable sheaves that can change their effective diameter. The belt or chain runs between the two pulleys, and its position on the sheaves determines the gear ratio.

When the driver accelerates or decelerates, the variator adjusts the effective diameter of the pulleys to change the position of the belt on the sheaves. This, in turn, alters the gear ratio between the input and output shafts of the transmission. By continuously adjusting the effective diameter of the pulleys, the variator allows the CVT to provide an infinite number of gear ratios within its range.

During acceleration, the variator increases the effective diameter of the driving pulley and decreases the effective diameter of the driven pulley. This causes the belt to ride higher on the driving pulley and lower on the driven pulley, resulting in a higher gear ratio. As a result, the engine can operate at higher RPMs while the vehicle accelerates smoothly.

Conversely, during deceleration or cruising, the variator adjusts the effective diameters to lower the gear ratio. This allows the engine to operate at lower RPMs, improving fuel efficiency and reducing noise levels.

The variator continuously monitors the driving conditions and adjusts the gear ratio accordingly to provide optimal performance, whether it's for smooth acceleration, efficient cruising, or maintaining a constant speed. The adjustments are typically controlled by a computer, which takes into account factors such as throttle position, vehicle speed, engine load, and driver inputs.

In summary, the variator in a CVT is responsible for continuously varying the gear ratio by adjusting the effective diameter of the pulleys. It allows the CVT to offer a wide range of gear ratios without discrete gears, providing smooth acceleration, improved fuel efficiency, and optimized performance in various driving conditions.

editor by CX 2024-03-26