Product Description

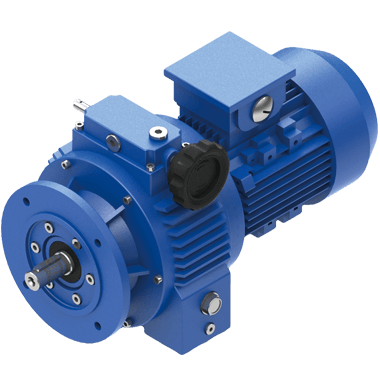

JWB Series Speed Variator

1. Features:

JWB-X type

- Sizes: ≥04

- Power up to 1.5 kW or more

- Cases in RAL 5571 blue cast iron

- Shafts: case hardened and tempered steel.

- Internal components: heat-treated steel

- Output speed with 4 pole(1400r/min) motors: 2-10r/min;4.7-23.5r/min;15-75r/min;20-100r/min, 28-140r/min, 30-150r/min;40-200r/min;60-300r/min;80-400r/min;100-500r/min;190-950r/min.

- Output Torque value max 1002Nm

- Silent, vibration-free running

- Bidirectional rotation

- Control handwheel positionable on either side

- Slipping speed to max load at 5%

- Regulation sensibility: 0,5 rpm

- Painted with blue epoxy-polyester powder

JWB-X B type

- Sizes:01,02,03 and 04

- Power up to 1.5 kW or less

- Cases in die-cast aluminium alloy

- Shafts: case hardened and tempered steel.

- Internal components: heat-treated steel

- Output speed with 4 pole(1400r/min) motors: 2r/min-20r/min;4.7r/min-23.5r/min;6.5-32.5r/min, 8-40r/min, 9-45r/min, 13-65r/min, 15r/min-75r/min;18-90r/min, 25-125r/min, 28r/min-140r/min;40r/min-200r/min;60r/min-300r/min;80r/min-400r/min;100r/min-500r/min;190r/min-950r/min.

- Output Torque value max 795 Nm

- Silent, vibration-free running

- Bidirectional rotation

- Control hand wheel positionable on either side

- Slipping speed to max load at 5%

- Regulation sensibility: 0,5 rpm

- Painted with blue epoxy-polyester powder

2. Technical parameters

| Type | Output Torque | Output Shaft Dia. | Output Speed Range | 2rpm-950rpm | |

| SWB01 | 2.6-1.6N.m | φ11 | Applicable Motor Power | 0.18kW-7.5kW | |

| SWB02 | 258-1.8N.m | φ14,φ24,φ28,φ32 | |||

| SWB03 | 426-4N.m | φ24,φ28,φ38 | Input Options | With Inline AC Motor | |

| SWB04 | 795-8N.m | φ28,φ38,φ42 | With IEC Motor | ||

| SWB05 | 535-16N.m | φ38,φ48,φ55 | With Input Shaft | ||

| SWB06 | 1002-40N.m | φ42,φ55,φ70 | With Input Flange | ||

About Us

ZheJiang CHINAMFG Drive Co.,Ltd,the predecessor was a state-owned military mould enterprise, was established in 1965. CHINAMFG specializes in the complete power transmission solution for high-end equipment manufacturing industries based on the aim of "Platform Product, Application Design and Professional Service".

CHINAMFG have a strong technical force with over 350 employees at present, including over 30 engineering technicians, 30 quality inspectors, covering an area of 80000 square CHINAMFG and kinds of advanced processing machines and testing equipments. We have a good foundation for the industry application development and service of high-end speed reducers & variators owning to the provincial engineering technology research center,the lab of gear speed reducers, and the base of modern R&D.

Our Team

Quality Control

Quality:Insist on Improvement,Strive for Excellence With the development of equipment manufacturing indurstry,customer never satirsfy with the current quality of our products,on the contrary,wcreate the value of quality.

Quality policy:to enhance the overall level in the field of power transmission

Quality View:Continuous Improvement , pursuit of excellence

Quality Philosophy:Quality creates value

3. Incoming Quality Control

To establish the AQL acceptable level of incoming material control, to provide the material for the whole inspection, sampling, immunity. On the acceptance of qualified products to warehousing, substandard goods to take return, check, rework, rework inspection; responsible for tracking bad, to monitor the supplier to take corrective

measures to prevent recurrence.

4. Process Quality Control

The manufacturing site of the first examination, inspection and final inspection, sampling according to the requirements of some projects, judging the quality change trend;

found abnormal phenomenon of manufacturing, and supervise the production department to improve, eliminate the abnormal phenomenon or state.

5. FQC(Final QC)

After the manufacturing department will complete the product, stand in the customer's position on the finished product quality verification, in order to ensure the quality of

customer expectations and needs.

6. OQC(Outgoing QC)

After the product sample inspection to determine the qualified, allowing storage, but when the finished product from the warehouse before the formal delivery of the goods, there is a check, this is called the shipment inspection.Check content:In the warehouse storage and transfer status to confirm, while confirming the delivery of the

product is a product inspection to determine the qualified products.

7. Certification.

Packing

Delivery

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(",").forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Motor, Machinery, Agricultural Machinery, Ceramic |

|---|---|

| Hardness: | Hardened Tooth Surface |

| Installation: | Vertical or Horizotal Type |

| Layout: | Coaxial |

| Gear Shape: | Planetary Conedisk Friction Type |

| Step: | Stepless |

| Customization: |

Available

|

|

|---|

What factors should be considered when selecting a variator for different industrial applications?

When selecting a variator for different industrial applications, several factors need to be considered to ensure optimal performance and compatibility. Here are the key factors that should be taken into account:

1. Load Requirements:

The first factor to consider is the load requirements of the specific industrial application. Determine the torque and power demands of the machinery or equipment that the variator will be driving. It is essential to select a variator that can handle the anticipated load conditions without exceeding its maximum torque or power capabilities. Consider factors such as starting torque, peak torque, and continuous torque requirements to ensure the variator can handle the load effectively.

2. Speed Range:

Consider the required speed range for the application. Determine the minimum and maximum speeds that the variator needs to achieve. Variators are designed to operate within specific speed ranges, so it is crucial to select a model that can accommodate the required speed range while maintaining optimal performance. Additionally, consider the desired speed resolution or increments required for precise speed control.

3. Environmental Conditions:

Take into account the environmental conditions in which the variator will operate. Factors such as temperature, humidity, dust, and vibration levels can impact the performance and longevity of the variator. Choose a variator that is designed to withstand the specific environmental conditions of the industrial application. For example, some variators are specifically designed for harsh or hazardous environments and have enhanced protection against dust, moisture, or extreme temperatures.

4. Control System Integration:

Determine how the variator will integrate with the control system of the industrial application. Consider compatibility with existing control interfaces or protocols, such as analog, digital, or fieldbus systems. Ensure that the variator can be easily integrated into the control architecture of the machinery or equipment, allowing for seamless communication and control. Compatibility with programmable logic controllers (PLCs) or other control devices should also be evaluated.

5. Operational Efficiency:

Evaluate the operational efficiency of the variator. Look for features that contribute to energy efficiency, such as low power losses or regenerative capabilities. A variator that operates efficiently can help reduce energy consumption, lower operating costs, and minimize the environmental impact. Consider features like automatic energy optimization, energy monitoring, or sleep modes that can enhance the overall efficiency of the variator.

6. Maintenance and Serviceability:

Consider the ease of maintenance and serviceability of the variator. Look for features that simplify maintenance tasks, such as accessible components, user-friendly interfaces, and diagnostic capabilities. Additionally, consider the availability of spare parts and the reputation of the manufacturer or supplier in terms of customer support and after-sales service.

7. Cost and Budget:

Finally, evaluate the cost of the variator and its alignment with the budget for the industrial application. Consider the initial purchase cost as well as the long-term operational costs, including energy consumption, maintenance, and potential downtime. It is important to strike a balance between the desired features, performance, and cost-effectiveness to ensure the best value for the specific application.

By considering these factors - load requirements, speed range, environmental conditions, control system integration, operational efficiency, maintenance and serviceability, and cost - when selecting a variator for different industrial applications, you can make an informed decision that meets the specific needs of the machinery or equipment, ensuring reliable and efficient operation.

Can you provide insights into the importance of proper variator alignment?

Proper variator alignment is of utmost importance for the optimal performance and longevity of variator systems. The alignment refers to the precise positioning and alignment of the variator components, including the drive and driven pulleys, belts, and associated hardware. Here are some insights into the importance of proper variator alignment:

1. Efficient Power Transfer:

Proper variator alignment ensures efficient power transfer from the engine to the driven wheels. When the variator components are properly aligned, there is minimal power loss due to misalignment or slippage. This efficient power transfer allows the vehicle to operate at its maximum performance potential, providing better acceleration, smoother shifts, and improved fuel efficiency.

2. Optimal Belt Performance:

Variators rely on belts to transmit power between the drive and driven pulleys. Proper alignment ensures that the belts operate within their designed specifications. Misalignment can cause the belts to run off-center or at an angle, leading to increased wear, premature belt failure, and reduced overall performance. Aligning the variator components correctly ensures that the belts are properly tensioned and positioned, maximizing their lifespan and performance.

3. Reduced Wear and Tear:

Misalignment can result in excessive friction, heat buildup, and increased wear on the variator components. The misaligned pulleys and belts can cause uneven distribution of forces and place additional stress on the bearings, shafts, and other mechanical parts. Over time, this can lead to accelerated wear, premature failure of components, and costly repairs. Proper variator alignment helps minimize these issues, reducing wear and tear and increasing the lifespan of the system.

4. Smooth Operation:

Proper alignment contributes to smooth and seamless operation of the variator system. When the variator components are aligned correctly, the gear ratio changes occur smoothly without jerks or vibrations. This smooth operation improves the overall driving experience, ensuring comfortable shifts and consistent power delivery. Misalignment can result in erratic behavior, such as belt slippage, juddering, or sudden changes in power output, compromising the vehicle's performance and drivability.

5. Prevents Excessive Noise and Vibration:

Misaligned variator components can generate excessive noise and vibration during operation. The misalignment can cause the belts to rub against the pulleys, leading to squealing or chirping noises. In addition, vibrations may occur due to the imbalanced forces generated by misaligned components. Proper variator alignment helps minimize these noise and vibration issues, ensuring a quieter and smoother operation of the system.

6. Avoids Premature Component Failure:

Misalignment places undue stress on the variator components, increasing the risk of premature failure. Bearings, shafts, pulleys, and other mechanical parts can experience excessive wear, fatigue, or damage when subjected to misalignment-related forces. By aligning the variator components correctly, the load is distributed evenly, reducing the risk of premature failure and extending the lifespan of the system.

7. Consistent Performance and Efficiency:

Proper variator alignment ensures consistent performance and efficiency throughout the lifespan of the system. When the components are aligned correctly, the variator operates as intended, delivering consistent gear shifts, power delivery, and fuel efficiency. Consistency in performance and efficiency is vital for a reliable and enjoyable driving experience.

In conclusion, proper variator alignment is essential for the optimal performance, longevity, and reliability of variator systems. It ensures efficient power transfer, optimal belt performance, reduced wear and tear, smooth operation, minimized noise and vibration, avoidance of premature component failure, and consistent performance and efficiency. Regular inspection and maintenance, along with professional alignment when necessary, are crucial to maintaining proper variator alignment and maximizing the benefits of the system.

Are there specific applications where variators outperform other transmission systems?

Yes, there are specific applications where variators, particularly those used in continuously variable transmissions (CVTs), can outperform other transmission systems. The unique characteristics and capabilities of variators make them well-suited for certain scenarios. Here's a detailed explanation of the specific applications where variators outperform other transmission systems:

1. Urban Driving and Stop-and-Go Traffic:

Variators excel in urban driving conditions and stop-and-go traffic situations. In congested areas with frequent speed changes, variators offer seamless and continuous gear ratio adjustment. This allows the engine to operate at optimal RPM levels, resulting in improved fuel efficiency and smooth power delivery. The absence of discrete gear shifts eliminates the need to constantly shift gears, providing a more effortless and comfortable driving experience.

2. Hill Climbing and Off-Road Driving:

When it comes to tackling steep inclines or challenging off-road terrains, variators can outperform other transmission systems. The continuous gear ratio adjustment of variators ensures that the engine maintains the appropriate power and torque delivery for climbing hills or traversing rough terrain. This adaptability allows vehicles equipped with variators to maintain momentum and traction, providing superior performance and control in demanding off-road conditions.

3. Smooth and Responsive Acceleration:

Variators offer excellent performance in terms of smooth and responsive acceleration. The stepless gear shifts provided by variators eliminate the jolts or interruptions in power delivery that can occur with traditional gear systems. This seamless acceleration allows for quick and efficient merging onto highways, overtaking other vehicles, or responding to sudden changes in traffic conditions. Variators can deliver a more engaging driving experience by providing instant response to throttle inputs.

4. Hybrid and Electric Vehicles:

Variators have proven to be advantageous in hybrid and electric vehicles. In hybrid vehicles, variators can be used in combination with internal combustion engines and electric motors to optimize efficiency and power delivery. The continuous gear ratio adjustment of variators allows for seamless integration between the different power sources, ensuring that the engine operates within its most efficient range. In electric vehicles, variators can be utilized to provide a smooth and efficient transfer of power from the electric motor to the wheels.

5. High-Performance Sports Cars:

In certain high-performance sports cars, variators can outperform traditional gear systems. Variators offer the advantage of quick and precise gear ratio adjustment, allowing the engine to stay within its optimal power band during aggressive acceleration and high-speed driving. This results in enhanced performance, improved acceleration, and seamless power delivery, making variators an attractive choice for sports car enthusiasts.

6. Fuel Efficiency and Emission Reduction:

Variators, especially those used in CVTs, are known for their potential to improve fuel efficiency and reduce emissions. The continuous gear ratio adjustment ensures that the engine operates at the most efficient RPM, maximizing fuel economy. By avoiding inefficient gear shifts, variators contribute to reduced fuel consumption and lower emissions, making them a preferred choice for eco-friendly and fuel-conscious vehicles.

In summary, variators can outperform other transmission systems in specific applications such as urban driving, stop-and-go traffic, hill climbing, off-road driving, smooth and responsive acceleration, hybrid and electric vehicles, high-performance sports cars, and fuel efficiency-focused applications. The unique characteristics of variators, including continuous gear ratio adjustment and seamless power delivery, make them well-suited for these scenarios, offering advantages in terms of performance, control, and efficiency.

editor by CX 2024-03-13